Beginners Guide to “Oil-Based” Furniture Paint: From Linseed to Alkyd

Pull up a chair, friend, because we’re about to time-travel through the gloriously messy, brilliant, and sometimes smelly history of oil-based paint. If you’ve ever cracked open a can of oil enamel and wondered how we got from squishing flax seeds to stirring glossy alkyds, this one’s for you.

THIS POST CONTAINS AFFILIATE LINKS TO PRODUCTS THAT I HAVE OR WOULD USE.

AS AN AMAZON ASSOCIATE, I EARN FROM QUALIFYING PURCHASES AT NO COST TO YOU.

YOU CAN SEE MY FULL DISCLOSURE HERE.

Oil paints weren’t invented in one “Eureka!” moment—they evolved slowly, adapting to the needs of artists, builders, and eventually DIYers like us. Let’s trace the lineage:

| Era | Development | What It Meant for Furniture & Craft |

|---|---|---|

| Ancient Times (pre-5th century CE) | Egyptians and Romans used drying oils like linseed, walnut, and poppy seed as binders for pigments. These weren’t paints as we know them, more like protective and decorative oils with color mixed in. | Furniture finishes were primitive but durable—think oiled wood with earth pigments. Gorgeous in its simplicity, but not glossy or long-lasting. |

| Middle Ages (5th–15th century) | Oil-based pigments were mostly used in manuscripts, craft guild work, and some rudimentary panel painting. Recipes were secret, inconsistent, and slow-drying. | Furniture wasn’t typically “painted” with oils yet—mostly stained, waxed, or gilded. Oils were too unreliable for broad household use. |

| Renaissance Boom (15th century) | Artists like Jan van Eyck popularized oil painting on canvas and wood panels. Linseed oil emerged as the superstar binder, prized for clarity and durability. | Techniques from fine art slowly bled into decorative arts. The idea of painting furniture with oils started simmering. |

| 18th Century | Oil paints became more standardized and available commercially. Linseed oil paints were common for doors, trim, and furniture—but slow drying was still a major frustration. | Furniture makers began embracing oil paint for durable, pigmented finishes. Think farmhouse tables and painted cabinetry. |

| 19th Century Industrial Revolution | Mass production of linseed oil paints in tins. Widespread use in homes, ships, and furniture. Still natural, still slow to cure, but finally accessible. | Painted furniture became more popular in middle-class homes. Painted kitchen dressers and chests became staples. |

| 1920s–1930s | The big breakthrough: alkyd resins were invented. These were synthetic modifications of natural oils, made by reacting polyols with acids. Result: faster drying, tougher, more versatile paints. | Suddenly, oil paints weren’t just slow, fussy brews. Alkyd enamels gave furniture a sleek, hard, modern finish. Perfect for the Deco and Mid-Century eras. |

| Mid-20th Century | Alkyd paints dominated architectural and furniture finishes. Brands began labeling them “oil-based” or “enamel” interchangeably. | Furniture painters loved the smooth, durable coats. Downsides: strong odor, yellowing over time, and the dreaded turpentine cleanup. |

| Late 20th–21st Century | Environmental and health regulations pushed manufacturers to reformulate. Lower VOC versions appeared, but water-based paints began to steal the show. | Today, oil/alkyd paints are still used for durability and rich finishes, but often marketed as “professional” or “advanced” products rather than DIY-friendly defaults. |

The Humble Beginnings: Drying Oils and Pigments

Long before paint cans lined hardware store shelves, humans were mixing earth pigments with natural binders to decorate caves and temples. The “oil” in oil-based paint came into the spotlight during the Middle Ages, when craftsmen and artists discovered that drying oils, like linseed, tung, and walnut oil, could hold pigment particles together and harden into a protective surface.

- Chemistry 101: Drying oils are triglycerides with fatty acids that react with oxygen. That slow chemical reaction is called oxidative polymerization—basically, the oil “dries” into a solid film.

- Artistry Meets Utility: Oil paints revolutionized fine art in the Renaissance (think Van Eyck and Da Vinci), but they weren’t just for portraits—they also sealed wood, masonry, and metal in practical settings.

At this stage, paint was literally hand-mixed. No two batches were the same, and quality varied depending on the purity of oils, pigments, and the skill of the painter.

Industrial Revolution: Enter the Factory Can

By the 18th and 19th centuries, industries wanted finishes that could be produced consistently, shipped easily, and used on demand. Enter the birth of commercial oil paints: linseed oil blended with ground pigments and sold in tins.

- These paints were thick, slow-drying, smelly, and temperamental in cold weather.

- Linseed oil, though durable, tended to yellow over time, which annoyed both homeowners and artists.

Still, for a while, linseed-oil paints were king: they were tough, protective, and relatively cheap. Perfect for barns, wagons, and eventually industrial machinery.

Chemistry Gets Fancy: The Birth of Alkyds (1920s-1930s)

By the early 20th century, chemists were on a mission to create synthetic resins that could mimic oils but with fewer drawbacks. Enter alkyd resins, invented in the 1920s.

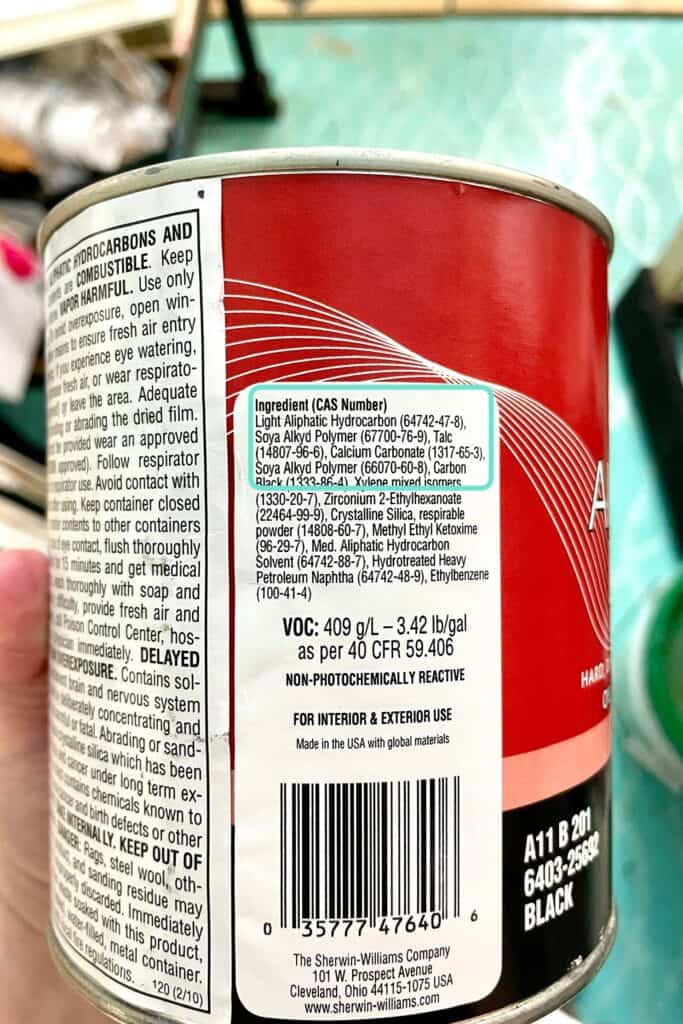

- What’s an alkyd? The word comes from “alcohol” + “acid.” Alkyd resins are polyester resins modified with fatty acids (often soybean or linseed).

- This gave paint makers the best of both worlds:

- The toughness of synthetic polymers

- The flexibility and adhesion of natural oils

By the 1930s, alkyd-based paints started replacing pure linseed-oil paints in both architectural and industrial use. They dried faster, yellowed less, and could be formulated for a smoother, glossier finish.

The “Enamel” Label Appears

Around the same time, marketing departments got involved. “Enamel” became a buzzword to describe any oil or alkyd paint that dried to a hard, glossy, washable surface.

- Historically, “enamel” referred to a glassy, kiln-fired coating.

- Paint companies borrowed the term because it sounded high-end and durable.

- The result? Confusion that still haunts us: enamel is not a formula, it’s a finish description.

So, oil paint, alkyd paint, and enamel paint overlap.

- A “true” oil paint = pigment + drying oil (linseed, tung, walnut).

- An alkyd paint = pigment + alkyd resin (synthetic oil-modified resin).

- An “enamel” = marketing term for a glossy oil/alkyd paint.

Mid-20th Century: Oil Paint at Its Peak

From the 1940s to 1960s, oil and alkyd paints ruled the world. They were:

- Durable

- Glossy

- Scrubbable

- Widely available

If you had painted furniture or trim in your grandmother’s house, it was probably oil-based or alkyd enamel.

Regulations, Water, and the Slow Goodbye (1970s Onward)

Then came two big changes:

- Environmental & health concerns

- Oil and alkyd paints rely on strong solvents (mineral spirits, turpentine, later high-VOC thinners).

- By the 1970s–80s, VOC (volatile organic compound) restrictions began limiting traditional formulas.

- Water-based innovations

- Acrylic and latex paints improved dramatically, drying fast with less odor.

- They became the “go-to” choice for homeowners, leaving oil paints to niche markets.

Today, oil-based paints are harder to find in many regions, though alkyd hybrids (like waterborne alkyds) keep the tradition alive in a more eco-friendly way.

Chemistry Snapshot: Natural Oil vs. Alkyd

| Feature | Natural Oil (Linseed) | Modern Alkyd |

|---|---|---|

| Binder | Linseed oil | Alkyd resin (modified oils + acids) |

| Drying Mechanism | Oxidation (slow) | Oxidation + chemical curing (faster, smoother) |

| Durability | Good but yellowing | Highly chip and scratch resistant |

| Furniture Use | Historical / niche | Standard today, widely available |

| Odor & Safety | Strong, flammable | Still solvent-based, but more controlled |

Why This History Still Matters for DIY Furniture Lovers

If you’re wondering why bother with oil paints at all when water-based options are everywhere, here’s the scoop:

- Durability: Oil/alkyd finishes can take more abuse.

- Predictability: Modern alkyds cure consistently, so you can plan coats and sanding.

- Look: They have a richness, depth, and gloss that’s hard to fake.

- Tradition: Some vintage furniture just begs for the authenticity of oil-based paint.

But there are trade-offs: long dry times (true oils), stronger fumes, and tougher cleanup. That’s why most modern DIYers dabble with alkyd hybrids rather than raw linseed blends.

💡 Quirky Fact: Some old-timers still swear by true linseed oil for antiques, claiming the “patina” is unmatched. But for functional, everyday furniture, alkyds are the reigning champions.

Fun Trivia Facts:

- Alkyd paints have been around since the 1930s, developed to outperform traditional oils in durability and drying time.

- Before alkyds, refinishing a dresser could take weeks because of the drying times, and that’s without the endless sanding!

- Even early Hollywood set designers loved alkyds because they gave that glossy, “camera-ready” finish without smudging under hot lights.

History aside, the takeaway is that this finish has a proven track record for furniture that lasts.

The Final Wrap-Up

Oil paints have evolved from decorating ancient Egyptian tombs to appearing on IKEA hacks on TikTok, a journey fueled by science, style, and sheer persistence.

- True oils gave us depth and tradition.

- Alkyds gave us speed and resilience.

- Enamels gave us marketing pizzazz.

And while water-based finishes may rule the shelves today, oil paints still hold their crown for anyone chasing that rich, durable, furniture-friendly glow.

So next time you’re eyeing a can of “oil-based enamel,” you’ll know that you’re holding the grandchild of flaxseed, raised on chemistry, polished by history, and still stubbornly stylish.

Until next time, have a beautiful and blessed day!

Don’t forget to sign up so you hear all about the next misadventure!